VESTA Commercial Filtration

VESTA® Filtration Systems are designed for commercial and industrial applications requiring treated water for turbidity removal, iron removal, or taste and odor control at flow rates up to 625 GPM. With a wide variety of filter media available, we can manufacture to unique specifications in a single or a combination of multiple tank systems to meet your specific requirements. With our dedication, you can be assured that VESTA will provide you with the support you deserve.

Water Quality Makes a Difference

Many water supplies, municipal and groundwater, contain iron, rust, suspended particles, dissolved minerals, sediment, and unpleasant odors. Large and small industries rely on water for processes such as cooling, heating, cleaning or rinsing, and consumption. Slime and scale form on pipes, boilers, heat exchangers, and cooling towers, reducing the heat transfer capabilities of a system as well as increasing the cost of operating the system. VESTA Filtration Systems are designed to reduce or eliminate these unwanted contaminants and improve process efficiency, saving money now and in the years ahead.

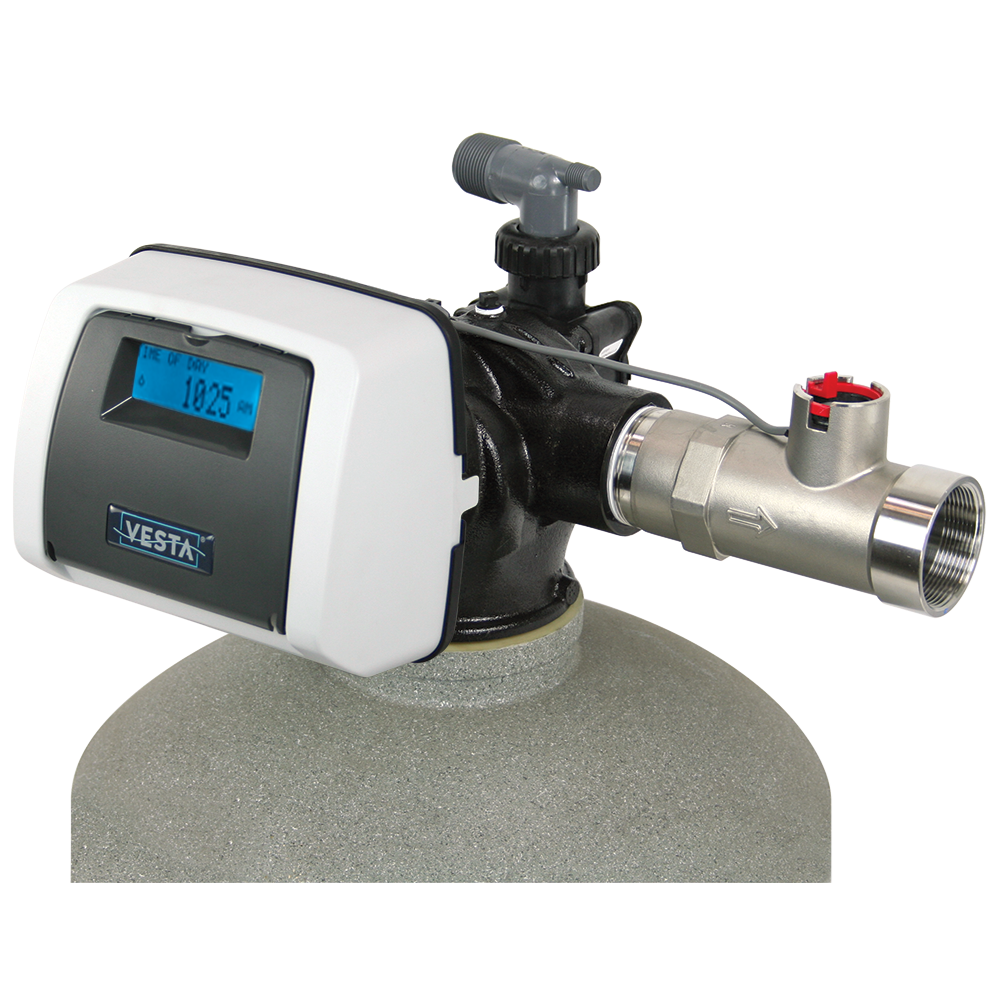

VESTA Filtration Systems are always built for each client to provide years of trouble-free service, even in the most demanding applications. By sizing and matching the control valve, pressure vessel(s), and media, many unwanted minerals, chemicals, tastes, and odors or bacteria can be removed. In addition, these systems can be combined and used as pre-treatment or post-treatment to other water treatment systems or as a stand-alone water treatment solution.

Key Features

- TURBIDITY (Sediment) FILTRATION SYSTEMS - Sand filters use a bed of fine mesh sand coupled with a layer of course gravel to effectively remove suspended solids and turbidity up to 20 microns.

- Multi-media depth FILTRATION SYSTEMS (Sediment) offer a greater amount of filtration of finer solids down to 10 microns. Multi-Media filters consist of multiple layers of media - from course to fine. The course media layers reside at the top of the tank and the finer at the bottom. The course layers trap the largest particles and the finer layers at the bottom of the tank trap the smallest particles effectively using the entire bed “depth” for filtration of the problem water. Anthracite, sand, 2 grades of garnet with a support bed of gravel are used, and with the specific gravities of each, will restratify after backwashing.

- FILTER-AG® - Filter-Ag® has many outstanding advantages over the more common granular filter media used for suspended solids reduction. Its fractured edges and irregular surface provides a high surface area and complex flow path for efficient removal of suspended matter through out the filter bed, typically reducing suspended solids down to the 20-40 micron range. The larger particle size creates less pressure loss through the filter and allows deeper sediment penetration into the bed for higher sediment loading and longer filter runs.

- ACTIVATED CARBON SYSTEMS are best for removal of chlorine, dissolved organic contaminants, tannins, color, phenols, and unpleasant tastes and odors. The activation process of carbon determines what adsorption and filtering characteristics the carbon will possess, as well as determine what can be filtered out of the water.The availability of numerous types of carbons today make activated carbon filters a versatile solution for a wide variety of water problems.

- IRON FILTERS - Manganese Greensand filters provide an excellent removal of iron and manganese. Manganese greensand is a purple-black filter medium that is used for the removal of soluble iron, manganese and hydrogen sulfide from water supplies. As the water passes through a greensand filter, any iron and manganese present is oxidized and trapped by the media. Backwashing and rinsing of the media removes the contaminates.